COB LED Strip Supplier & Manufacturer

lumiwise Lighting is one of top custom flexible COB LED Strip Light manufactures in China. We offer customized solutions, OEM, ODM service. Wholesalers, distributors, dealers, traders, agents are welcome to purchase in bulk with us.

All our COB LED Tape Lights are CE, RoHS and LM80 certificated, ensuring high performance and long lifetime.

If you have customized need for bulk robus Red, RGB, RGBW COB LED Strip Lights, lumiwise can offer custom COB LED Strip Light with custom color, size, long, CRI, and various accessories.

What is COB?

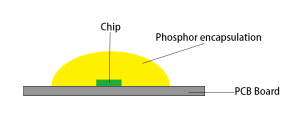

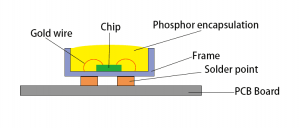

COB stands for Chip on Board in the LED field, which basically means that the LED chip is packaged directly on the circuit board (PCB). “Chip on Board” LEDs for flexible cob led strip lights are sometimes referred to as flip-chips.

Flip chip LEDs are basically a bare-bones approach to LED construction. Take a look at an ordinary SMD (Surface Mount Device) LED. It has a Lamp bead holder that package the LED chip and then covers it with a phosphor coating. The ‘flip chip’ that makes up the COB LED strip removes everything from its design, except for the LED chip, yellow phosphor cover layer, and connection pads.

COB VS SMD

What is COB LED Strip?

COB means Chips on Board, which means that the chips are directly encapsulated on the flexible PCB board, and the COB led strip is a strip of chips encapsulated on a flexible board. The chips are mostly flip-chips, which are linearly fixed on the PCB board, and then a layer of encapsulation glue mixed with phosphor is directly dropped on the surface of the chip. The light emitted from the chip is refracted, reflected, and interacts with the phosphor, and the glue emits different colors and color temperatures of light evenly.

Features & Benefits of COB LED Strip

Applications of COB LED strips

LEDYi is a professional COB LED Strip lights factory and exporter. The COB flexible LED strip that we manufacture is highly versatile and can be used in various different industries.

- Architectural lighting

- Furniture & wine cabinet lighting

- Holtel renovation lighting

- KTV & KTV bar lighting

- Parking lighting

- Shopping mall lighting

How To Produce COB LED Strip?

Step 1:Expanding Chips

Step 2:Die bonding

Step 3:Resistors onto FPCB

Step 4:Reflow-High temperature over 65 degrees for finished PCB with chips and resistors

Step 5:Fluorescent Powder glue mixing

Step 6:Drop the mixing glue on the surface of chips and resistors by auto glue machine

Step 7:Put glued cob led strip into the oven

Step 8:QC-testing the cob led strip after cooling

Step 9:Soldering the PCB into 5 meters per reel or the length as customer request

Step 10:Aging test, QC test, packing, then shipping

Cutting & Soldering COB LED Strip Lights

COB led strip can be cut just like smd led strip lights. Please only cut along the cut marks marked on the strip every 50mm (24) / 25mm (12V). This allows you to cut the strip to a custom size or add gaps to your application. The cut strips can be used again and are best connected by soldering, but if this is often not an option, our COB strip connectors also are available as an option.

Solder-free COB LED Strip Lights Connectors

If soldering is difficult for you, you can also use our solderless COB connectors.